03

Two layers and ROI

Schneider Electric Industries Bukowno estimates a fast return on investment period for the MiR500. The plant is able to reduce the costs of internal logistics and transport, as well as the number of pallets used – the ROI was calculated on this basis.

“The introduction of a mobile robot, capable of transporting two layers of products on one pallet, allows to place more goods in the truck. This helps us reduce transport costs. We are also using fewer pallets, which also reduces costs,” says Agnieszka Należnik-Jurek, Technical Department Manager, Schneider Electric.

MiR robots are also used at Schneider Electric plants in Bulgaria, Italy and France.

Mission: Improved transport efficiency

An operator or warehouse employee enters and approve the robot’s missions. Each mission entered in the Schneider Electric system indicates the transport of products from the production line to the warehouse. After receiving the mission, the robot takes an empty pallet from the warehouse and carries it to the production. Next, the MiR500 puts the empty pallet in an empty pallet rack, takes the pallet full of finished products and returns with it to the warehouse. If after reaching the warehouse there is no mission to complete at that time, the robot automatically drives and recharges.

“The old AGV line follower didn’t allow for any changes of the line, every time reconfiguration of the entire operation was required. Thanks to the flexibility of the MiR robot we can reorganize layout fast and with no additional costs, because there is no need for external support,” says Marcin Hat, Production Process Automation Engineer, Schneider Electric.

The MiR500 works around the clock in a three-shift system. The robot covers eight types of loops – the average length of each loop is 140 meters. During one shift, the robot covers an average of 5.5 – 6 km. If there is a need for any change in the robot's mission, e.g. because of minor modifications in the layout, all these changes are made by employees.

Optimizing the robot's work

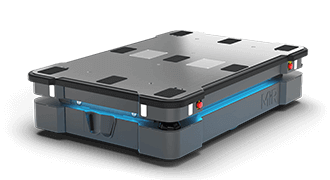

The MiR500 is equipped with a MiR Pallet Lift module for lifting, making it easier to lift entire pallets off the MiR Pallet Rack. The installed I/O sensors connected to the Wi-Fi network transmit the position of the robot on an ongoing basis. This allows constant monitoring of the route of transported pallets. In the SE Andon control system used in Bukowno, information about all orders and missions of the robot is available - this allows Schneider Electric to optimize their work. The tool constantly monitors all device parameters, such as charging time, distance travelled and percentage of charge in different periods of time.

Improving safety

360 degree lasers that constantly monitor the surroundings of the mobile robot, guarantee safety. Compared to the previously used AGV trolley, which could have overlooked the presence of man on its path, the MiR robot works safely in a dynamic environment – it detects people and machines, and stops or bypasses employees and obstacles. The 3D cameras and laser scanners are standard equipment of MiR robots.

Sound and light signalling also increases security. Just before entering rooms with people, the MiR500 signals its presence with a sound. After waiting the programmed amount of time, the robot enters the room. The MiR500 is also equipped with a blue spot – a mandatory blue light for moving machines at Schneider Electric.