02

issue & solution:

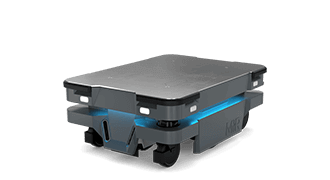

The management of the Łódź plants faced a challenge – how to combine the internal transportation of components between the production lines with loading and unloading automation. The solution to be used had to limit the role of humans in the transportation process. On the other hand, cost optimization and safety criteria had to be bet. The fleet of autonomous MiR200 robots has met these criteria, also providing flexibility in layout modifications and ease of programming and operation.

Industry 4.0 – plant productivity and safety improvement

Whirlpool bets on growth through automation, digitalization and Industry 4.0. This is how the company is improving its process effectiveness and quality of its products, also reducing costs and reinforcing its competitive position. MiR robots fit in well with this direction.

“At our factory, a dryer leaves the production line every 15 seconds. This requires transporting a huge number of components. Mobile robots provide us with a completely new way of delivering parts without human involvement. This enables employees to focus on higher value-added areas. Collaborative mobile robots also significantly improve safety, allowing us to avoid all potential collisions between people and devices such as forklifts or tuggers” – says Szymon Krupiński, Site Leader at Whirlpool company in Łódź.

Autonomous robots transport dryer components between two production lines

Robot transports dryer doors from the preassembly to the assembly line. On every run it carts 12 doors at a time and on the way back transports the empty packaging – the full loop is around 130 meters. MiR200 rides up to the preassembly line, moves under a loaded cart and hooks it up. The cart is then transported by the robot to the assembly line where full packages go. During the unloading, the empty boxes slide back to MiR’s cart under gravity. After that the robot returns to its starting point and the next transportation cycle begins.

Sensors and scanners allow the robot to detect obstacles appearing on its way, such as forklifts or tuggers, and avoid them. The full ride-cycle of the robot takes around 3 minutes and 50 seconds.

During the plant operation, two MiR200 robots with a load capacity of up to 200 kilograms are transporting the components while the third is docked in a charging station, serving as a backup.

Whirlpool has commenced the implementation in December 2018 with a test of the first robot. Subsequently, after a positive evaluation of the results, two additional MiR200 were put into use. Whirlpool installed also a robot fleet management system MiR Fleet, which allows the robots to properly queue the requests from the line and monitors their battery charge levels to ensure a continuous work.

Whirlpool’s implementation and configuration of the MiR robots at its Łódź plant was supported by Polish distributor – ProCobot.

The adaptability and user-friendliness of MiR robots increase efficiency

Since robots were implemented, the layout of the plant and thus the route the robots take has changed several times. Programming the MiR devices practically consists of specifying the points the robot has to travel through. The route should avoid places frequented by people to minimize the risk of collisions. The simplicity of operation, programming and advanced navigation technology allow the MiR robots to quickly adapt to changes in the production area layout.

“The ease of operation of MiR robots allows them to be used by staff without any engineering or programming background. This enables us to effectively utilize the robots without making big investments in training the employees in the context of the new technology” – says Paolo Aliverti, Logistic Program Manager Industry 4.0, Whirlpool.

MiR robots replace forklifts and ensure less than 2 year ROI

Before the robots were put into use, the transportation of components was performed solely with the use of vehicles operated by specifically trained employees – forklifts and tuggers. Three MiR robots can replace one such operator-driven vehicle. Thanks to the implementation of the autonomous mobile robots, forklift and tugger operators may focus on other tasks in the organization. The expected return on investment in mobile robots at the Łódź plant is maximum two years.

“By changing the system from human-operated to automated delivery we can boost productivity and engage employees to final product manufacturing. We are satisfied with the application implemented both in Łódź and in Radomsko. The MiR robots provide us with low cost of automation and flexibility in changing the plant layout. We consider the two-year return on investment as attractive” – says Adam Bakowicz, Process Technology Senior Engineer Industry 4.0, Whirlpool.

More intralogistics automation projects with MiR

Whirlpool intends to continue with the implementation of mobile robots in its plant in Łódź and also at other locations. Similar solutions are currently being tested at two Whirlpool plants in Italy, among others.