03

Benefits

Easy to use, easy to program

When people started to work with robots, they needed to learn how to cooperate and quickly understood a way they help them with everyday workload. In the beginning, it was quite new and hard to imagine for them to operate robots. Anyway, they quickly adopted to actively use robots to get all tasks done.

“We are now operating 14 robots in everyday use,” said Benjamin Paillusson, PC&L Improvement Leader in Faurecia Clean Mobility Písek. “As any other automation technology, it needs some supervision, anyway operation of MiR robots is very smooth and fully autonomous. From time to time, we just need to bring an improvement, but basically the technology does not need any human intervention.”

Instead of heavy tasks with manual loading and unloading materials and finished goods, employees on the shop floor can now focus on more valuable activities like supervision, being in the production, or programming robots. “The MiR interface is really user friendly, the way of building mission is very easy made through building blocks instead of code lines. Thus, it is understandable enough even for people without previous programming experience,” added Benjamin.

Return on investment less than 2 years

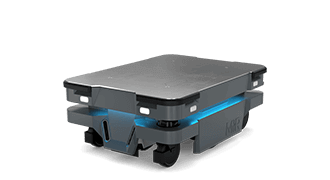

MiR mobile robots provide the customer with full autonomy enabling to easily set up new routes without additional magnetic tapes or other external guidance necessary for using other intralogistic technologies. The MiR robots and people can work well together, as robots are smart and can recognize people on the shop floor and they can stop or bypass people, which are around without decreasing the robots’ efficiency because the robot avoids bottlenecks..

“Mobile robots help us to bring more discipline to the shop floor and make our production processes more stable and reliable, especially important is stability for operating all three shifts. What we appreciate most on robots is their autonomy, meaning they move freely on the shop floor without any specifically needed equipment,” added Martin Horáček.

General benefits of deploying MiR mobile robots span into three main areas. The first is improved safety by eliminating forklifts on the shop floor. The second one is increased productivity in all areas of operations. And last but not least, it is return on investment into MiR robots: in Faurecia Písek the payback was less than 2 years.

“Our next automation plans are quite ambitious, as there are new locations to deploy MiR robots next year. In 2023, another big complex project here in Pisek called “Warehouse 4.0” is planned that fully automate materials flow from warehouse to production and from production to warehouse. Once completed, it will secure components delivery from warehouse to all 16 production lines by 10 MiR robots,” concluded Martin Horáček.