03

Pilot project leads to fully optimized production

The new line is intended to be the model for the eventual automation of all eleven production lines, with a fleet of MiR robots supporting them in a dynamic, highly efficient manufacturing floor in which each mobile robot can go where it’s needed when it’s needed to keep production flowing. Cabka estimates that the first MiR500 travels about three miles a day supporting one production line. With eleven lines planned for autonomous material transport with multiple MiR robots, workers and fork truck drivers will be relieved from many miles of manual material handling, allowing Cabka to redeploy those workers to higher-value tasks.

Robot features drive success

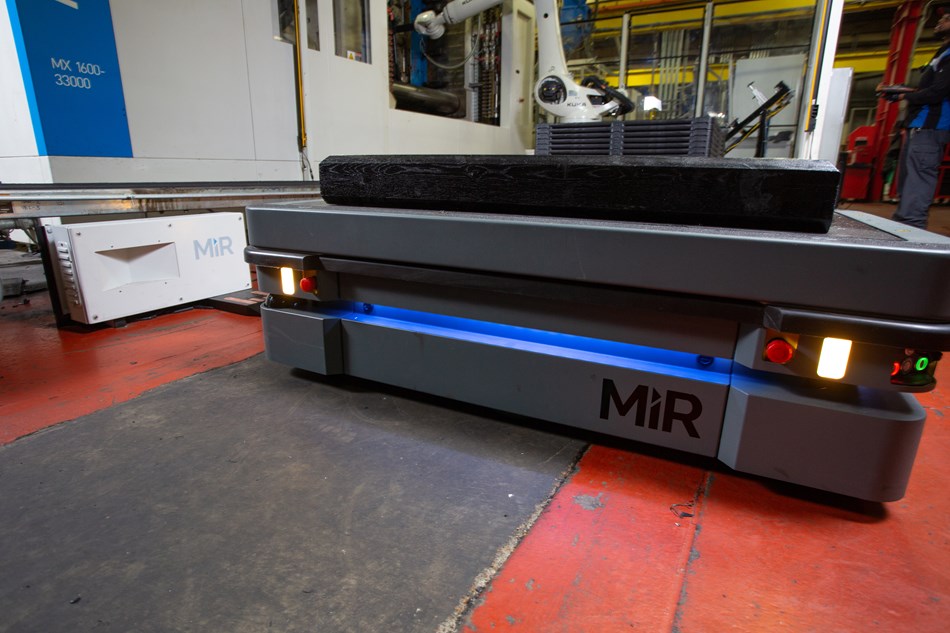

The MiR robot’s user-friendliness is a key element of the project’s success, along with the robot’s cost-effectiveness, small footprint, and safety features. And the MiR robots have proven to be the easiest part of the new automation project, even in an older facility with uneven floors, cracks, and bumps. “With the MiR500, we are very happy with the payload,” says Cabka project technician Craig Bossler. “It’s handled everything that we can stack on top of it. We haven’t found out how high we can go yet. It’s very stable—it can make turns, go straight, and it can hit bumps, and it’s always very stable. The MiR definitely can handle all the imperfections in the floor.”

Future plans look to expansion, focus on quality and customer needs

Cabka North America is looking at other ways to use the MiR robots as well, such as prepping orders overnight in the warehouse so they will be ready at the dock for loading in the morning. Patrick Garin, president of Cabka North America, anticipates that other Cabka locations will be following the North American facility’s lead. “We always have our corporate people come here—our corporate CEO and the other part of the team—and they will definitely be very interested in seeing our progress here,” he says.